During the first world war it was observed that when armour plating was hit by shrapnel some of the bits not only embedded themselves into the metal but ended up welded to it, a process that normally takes a great deal of heat. Laboratory tests later showed that if one material is accelerated fast enough into another they become plastic at the point of contact and fuse together, even at room temperature. This led to a process called explosive welding which, as its name suggests, uses chemical explosives spread over the top of a sheet of one material to blast it into a sheet below.

Explosive welding, for obvious reasons, is usually carried out in tunnels under mountains or in remote deserts. It is often employed to cover steel plate with a more expensive anti-corrosion layer of stainless steel or nickel alloy. This clad plate is typically used in chemical plants. Now the same idea, minus the explosives, is beginning to be used inside factories to make products ranging from white goods to aircraft and cars.

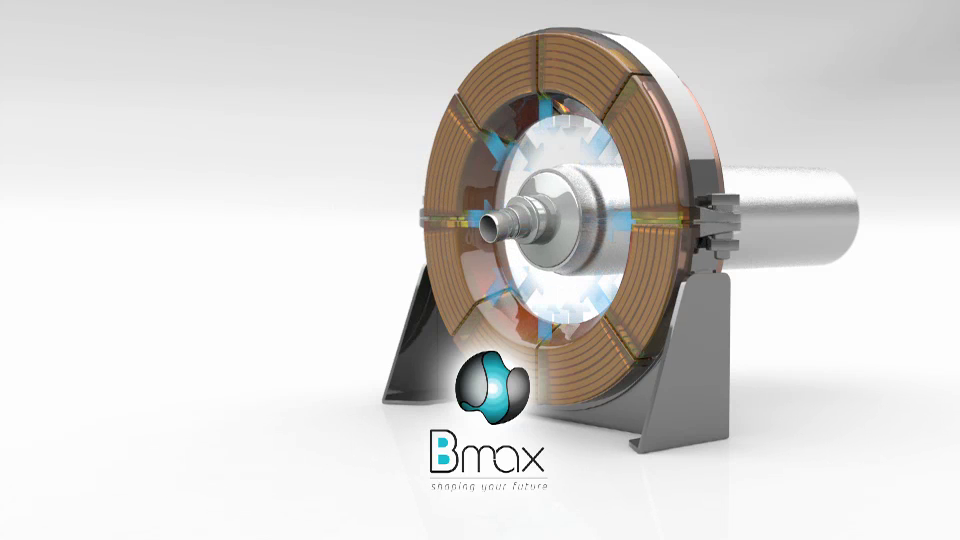

The process, known as magnetic-pulse welding, works a bit like the Large Hadron Collider near Geneva, accelerating materials into each other with extremely powerful magnetic forces, but on a less grand scale and with components rather than atomic particles. Bmax, based in Toulouse, France, has been developing the technology to produce machines that both weld components and shape them.

To do this two tubes, for example, are fitted together and placed inside one of the firm’s machines, where a coil generates an intense electromagnetic pulse in one of the tubes. This propels it into the other, over a distance of only a millimetre or so but in just a matter of microseconds (millionths of a second). When the two materials are forced together at such intensity, the atoms at the point of contact start sharing electrons, which fuses the components together. As no heat or melting is involved, dissimilar and difficult-to-weld materials can be joined, such as aluminium to copper and nickel to titanium. The same process can be used to shape materials, slamming down a sheet of metal onto a mould to make, say, the crease lines in the skin of a car door. Normally this is done with giant and noisy stamping presses.

A combination of factors has stimulated interest in the technology, says Rani Plaut, Bmax’s chief executive. Because the process operates at room temperature without clouds of welding sparks and fumes, it is cleaner and saves energy. It also produces stronger joins as conventional welds can be prone to corrosion. There is aesthetic value too, he adds: fused welds look much tidier than blobs of molten weld. And in shaping panels, lines can be made sharper than with conventional pressing. A process with roots in the noise and chaos of war may make the factory of the future a much quieter and cleaner place.

From the print edition: Science and technology