Heat Ventilation Air-Conditionning (HVAC)

Most automotive OEMs currently use R1234yf as the refrigerant of choice in the HVAC (Heat Ventilation & Air Conditioning) systems of their electric vehicles.

However, due to stricter environmental legislation regarding PFAs, many OEMs and thermal management system suppliers anticipate that regulations banning R1234yf will be progressively implemented in the coming years, and that the only viable alternative refrigerants will then be R744 (CO2) and R290 (Propane) natural refrigerants.

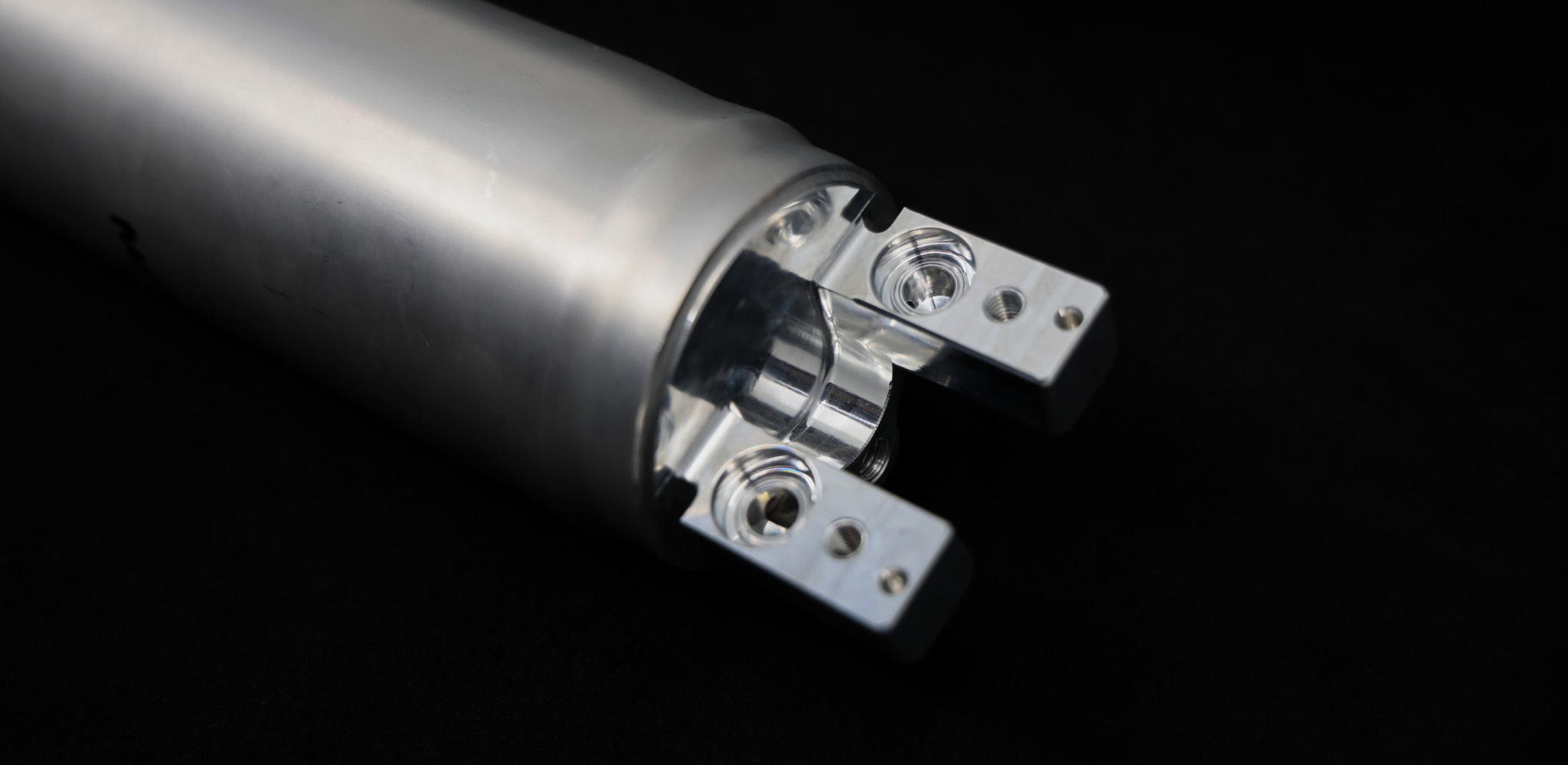

CO2 accumulators and Propane receiver driers are aluminum pressure vessels that are critical components of these new automotive HVAC systems. For cost-efficiency and maximum product efficiency and lifespan, their manufacturing requires a joining process that reduces material use, minimizes Total Cost of Ownership, avoids pollution by particles and ensures good corrosion resistance. MPW (Magnetic Pulse Welding) is the only viable option.

High Voltage Wire Harnesses

Electrification of heavy-duty vehicles is driving the demand for larger diameter wire sizes. MPC provides the most robust crimp with the lowest resistance and highest compaction. Pull testing results exceed requirements vs traditional crimping processes.

Our added value

Supported by the I-Pulse Inc. Group, a leader in HPP technologies, Bmax has full access to a worldwide network and thus enjoys international representation of its brand. In addition, as a member of the Group, it has a solid financial basis for its operations, making Bmax a reliable, long-term partner.

Our team is composed of world-class HPP experts and multidisciplinary, highly skilled technicians and engineers with a broad range of industrial experience. With a focus on continuous development and cutting-edge technology, we continually improve the overall performance of our systems.

At Bmax, customer satisfaction is a top priority. For over 12 years, we have invested substantial resources in R&D to offer you increasingly high-performing products. As an ISO 9001-certified company, we are committed to maintaining the highest standards of quality and excellence.

Bmax Systems are embedded with the highest level of machine security in the market. EC-certified with the support and assistance of an independent Certification Body, Bmax Systems are fully compliant with applicable regulations, technical standards and directives. Maximum Health & Safety for our Customers’ operators are guaranteed by comprehensive EMC measurements made by independent, specialized companies. Integrated lifting devices facilitate all tooling handling, enabling ergonomic, safe and easy operation and maintenance.

For years, Bmax has developed a range of compact and modular Systems that meet industry needs in terms of limited footprint and upgradeability. Designed for maximum versatility and adaptation to production changes, our workstations and tooling offer quick changeover times, enabling to easily switch production from one product reference to another one in a matter of minutes.

Our long-term technological roadmap enables our team to provide you with parts and systems with increased component lifetime and reliability, optimized production cycle times, easier maintenance, and user-friendly operation. Thanks to our systems’ modular design, all improvements can be integrated into already installed systems, enhancing Overall Equipment Efficiency over time.

Our dedicated maintenance team delivers best-in-class services, as well as spare parts & consumables. From training to maintenance, repair & retrofit, we customize our services to your specific needs and expectations thanks to flexible, comprehensive, and tailor-made Service Level Agreements.

Are you interested?

Contact us