MPF gives you the power to create complex and detailed shapes more efficiently and with less steps and equipment.

A special coil is placed near the metallic part, replacing the pusher in traditional forming. When the system releases its intense pulsed current, the coil generates a magnetic field which in turn accelerates the workpiece to hyper speed and onto the die.

At the impact, the extreme deformation speed transforms the metal into a viscoplastic state – increasing formability without affecting the original strength of the material.

Benefits Of Magnetic Pulse Forming

Product Performance

- Even material distribution

- Springback reduction

- Enables complex shapes with very fine details and sharp corners

- Extremely good capability to calibrate parts

High-quality surface finish of part

Green & Clean Process

- Uses low amounts of energy

- No pre- or post-form cleaning, no grease, no oil

Process Performance

- Higher formability (high velocity deformation)

- Less chance of tears due to friction as no contact occurs between tool and part

- Only requires a single one-sided die (1 MPF system can replace a heavy 5-step press system)

- Can be combined with any other forming technology

- Process can be applied to low conductive materials

- Cutting and perforating within same operation is possible in some cases

- Reliable and well suited to high-volume production

- Quick change over, resulting in time savings

Systèmes de formage

Technical Characteristics

Formage par Impulsion Magnétique : Pièces complexes pour structures aéronautiques

- Dimensions des tôles : jusqu’à L 1500 mm et 3,5 mm d’épaisseur – selon le grade des matériaux et la géométrie des pièces.

- Grades des matériaux : Toutes les séries d’aluminium Al 2xxx / Al 5xxx / Al 6xxx / Al 7xxx.

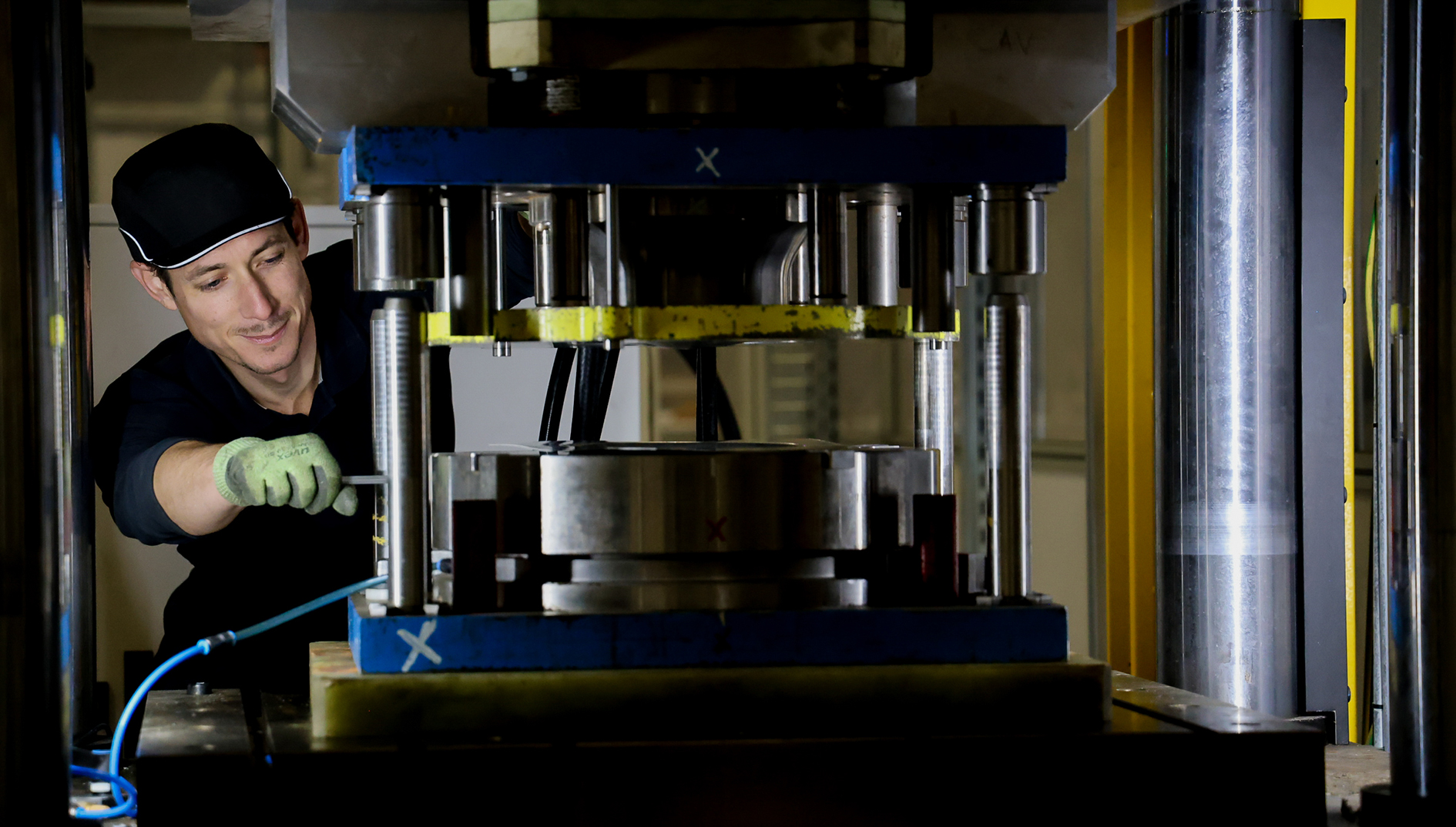

Formage Électrohydraulique : Pièces complexes pour moteurs et structures aéronautiques

- Dimensions globales des tôles : jusqu’à 800 mm x 800 mm.

Grades des matériaux :

- Aluminium : séries Al 2xxx / Al 5xxx / Al 6xxx / Al 7xxx jusqu’à 3,5 mm d’épaisseur.

- Acier et acier inoxydable : jusqu’à 1,6 mm d’épaisseur.

- Alliages à base de cobalt/nickel : jusqu’à 1,6 mm d’épaisseur.

- Autres matériaux/épaisseurs sur demande.

- Pas besoin de retouches manuelles, car il n’y a plus de retour élastique à corriger.

- Doté des plus hauts niveaux de sécurité machine sur le marché.

- Certifié CE avec le soutien d’un organisme de certification indépendant.

- Entièrement conforme aux réglementations, normes techniques et directives applicables.

- Empreinte optimisée de la cellule de production.

- Conception de la cellule de production selon les dimensions PN et les quantités.

- Processus hautement répétable : Cpk > 2.

- Pas de contact mécanique entre les outils et les pièces.

- Variations extrêmement faibles des impulsions magnétiques.

- Taux de rebut typique < 0,1 %.

- Système de suivi de processus entièrement intégré avec acquisition et enregistrement des données en temps réel.

- Facile à installer sur une presse hydraulique standard.

- Interface homme-machine conviviale (HMI).

- Accès aux outillages du système facilité.

- Portes sécurisées pour les opérations de maintenance.

- Assistance et maintenance à distance possibles.

- Fonctions de diagnostic en option.

- Faible consommation d’énergie électrique.

- Moins d’opérations de formage et d’étapes de recuit.

- Réduction de la consommation de matières premières.