With our innovative, clean, and exceptionally efficient technologies, as well as engineering and design expertise, Bmax empowers its customers to reduce production cycle times, save material, reduce weight and cost, while ensuring the highest level of product performance.

Systèmes de formage

Technical Characteristics

Exemples de produits

Formage par Impulsion Magnétique : Pièces complexes pour structures aéronautiques

- Dimensions des tôles : jusqu’à L 1500 mm et 3,5 mm d’épaisseur – selon le grade des matériaux et la géométrie des pièces.

- Grades des matériaux : Toutes les séries d’aluminium Al 2xxx / Al 5xxx / Al 6xxx / Al 7xxx.

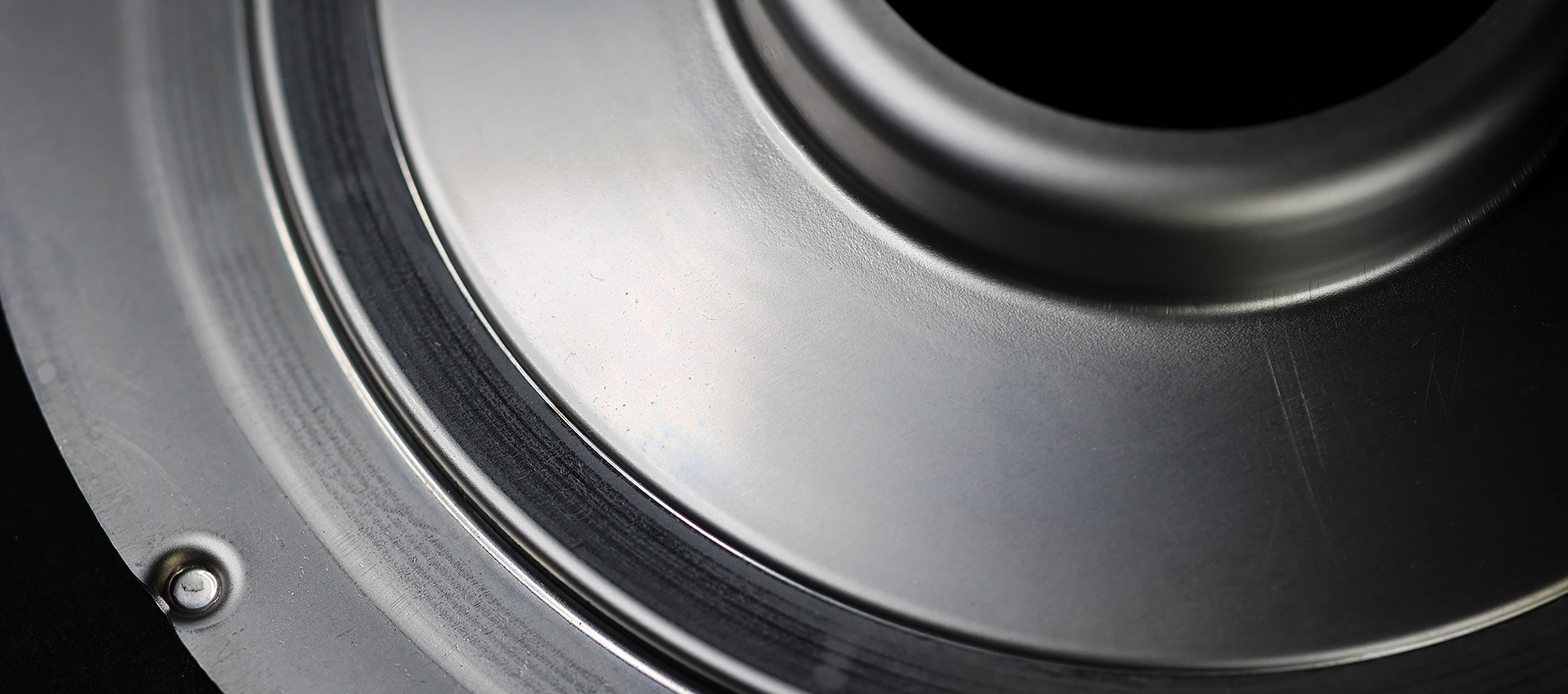

Formage Électrohydraulique : Pièces complexes pour moteurs et structures aéronautiques

- Dimensions globales des tôles : jusqu’à 800 mm x 800 mm.

Grades des matériaux :

- Aluminium : séries Al 2xxx / Al 5xxx / Al 6xxx / Al 7xxx jusqu’à 3,5 mm d’épaisseur.

- Acier et acier inoxydable : jusqu’à 1,6 mm d’épaisseur.

- Alliages à base de cobalt/nickel : jusqu’à 1,6 mm d’épaisseur.

- Autres matériaux/épaisseurs sur demande.

Sécurité, santé et sûreté

- Pas besoin de retouches manuelles, car il n’y a plus de retour élastique à corriger.

- Doté des plus hauts niveaux de sécurité machine sur le marché.

- Certifié CE avec le soutien d’un organisme de certification indépendant.

- Entièrement conforme aux réglementations, normes techniques et directives applicables.

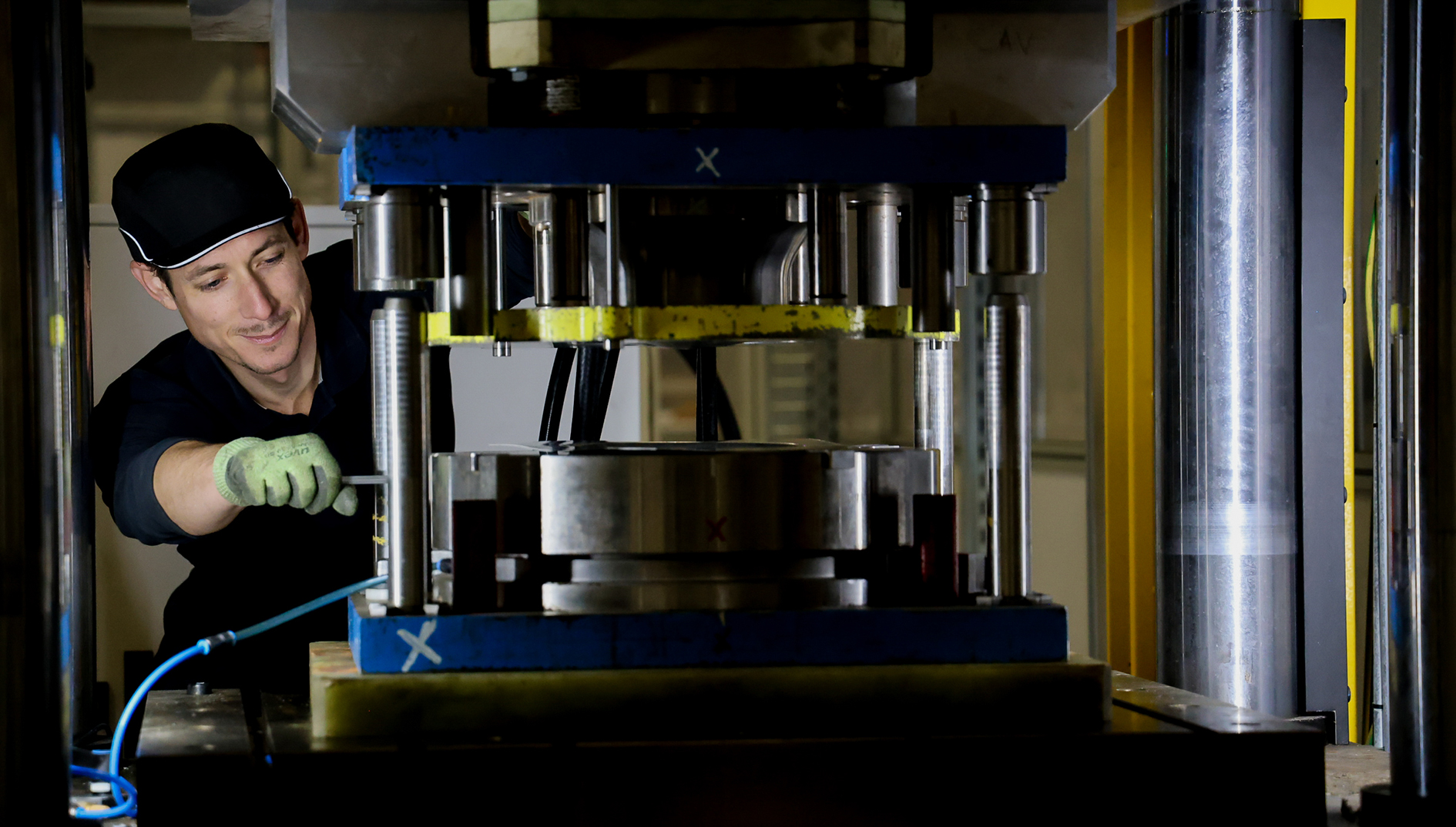

Production compacte, manuelle ou semi-automatique

- Empreinte optimisée de la cellule de production.

- Conception de la cellule de production selon les dimensions PN et les quantités.

Haute répétabilité, faible taux de rebut

- Processus hautement répétable : Cpk > 2.

- Pas de contact mécanique entre les outils et les pièces.

- Variations extrêmement faibles des impulsions magnétiques.

- Taux de rebut typique < 0,1 %.

Suivi du processus

- Système de suivi de processus entièrement intégré avec acquisition et enregistrement des données en temps réel.

Facilité d’utilisation et de maintenance

- Facile à installer sur une presse hydraulique standard.

- Interface homme-machine conviviale (HMI).

- Accès aux outillages du système facilité.

- Portes sécurisées pour les opérations de maintenance.

- Assistance et maintenance à distance possibles.

- Fonctions de diagnostic en option.

Respect de l’environnement

- Faible consommation d’énergie électrique.

- Moins d’opérations de formage et d’étapes de recuit.

- Réduction de la consommation de matières premières.

Products manufactured by our systems

Premium Technology

| Electro-Hydraulic Forming | Conventional Forming | |

| Number of Tools | 2 | 5 |

| Number of Forming Steps | 1 stamping + 1 EHF = 2 | 5 Stampings |

| Intermediate Thermal Treatments | 1 | 2 |

| Residual Internal Constraints | None No springback – No rework Parts geometrically compliant after EHF | High Springback 100% manual rework needed |

| Scrap Rate | < 0.1% | 20-25 % |

| Forming Quality & Aspect | Excellent quality & aesthetic <br>Very low thickness reduction <br>Even material distribution | Important thickness reduction<br>Uneven material distribution |

| Serial Manufacturing Time | 3.5 hours/part | 13-15 hours/part |

Other Solutions

Are you interested?

Contact us